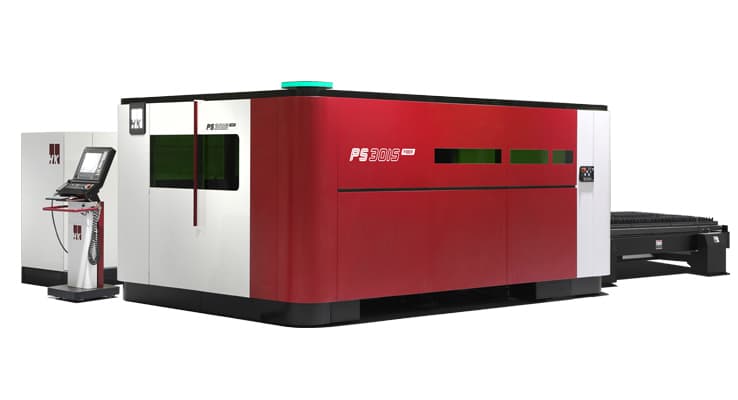

Fiber Laser

EZCAD 2.0 software is free to use on Microsoft Windows XP and Windows 2000. It can also be used with WIN 7, WIN8, and WIN 10 OS.

Laser machines using a fiber source laser use high precision field lens to increase the energy density of the laser beam and collimate it at one point.